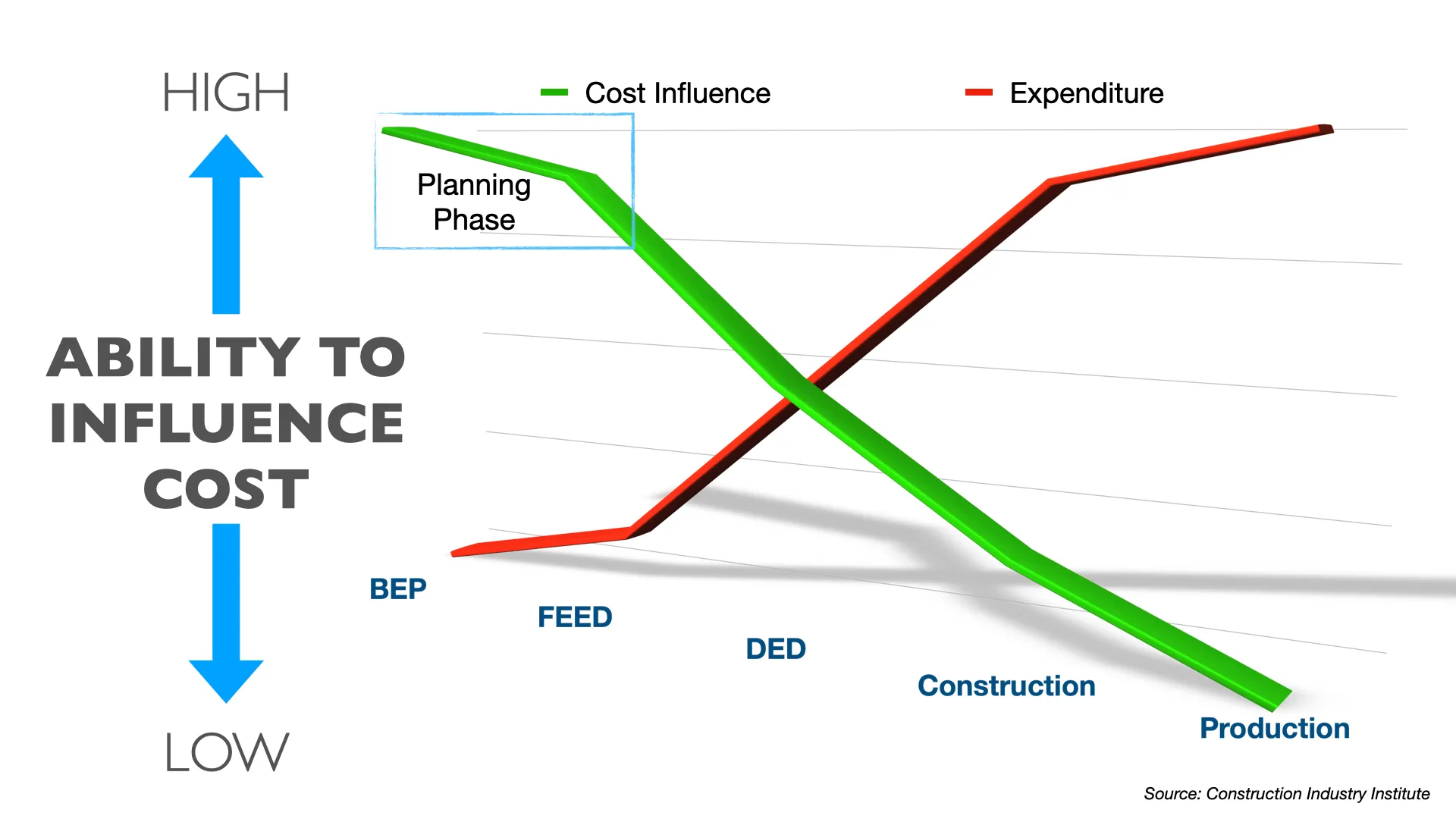

The Design Process — From Concept to Construction

A well-structured design process follows a phased approach, with each phase building on the previous one and narrowing the cost estimate accuracy:

Conceptual Design

Phase 1Define project scope, select technology, establish design basis

Key Deliverables

- Process block diagram

- Preliminary mass and energy balance

- Technology selection report

- Conceptual plant layout

- Initial CAPEX estimate (±30%)

Basic Engineering (FEED)

Phase 2Detailed process design, equipment sizing, preliminary P&IDs

Key Deliverables

- Process Flow Diagrams (PFDs)

- Piping & Instrumentation Diagrams (P&IDs)

- Equipment datasheets and specifications

- Utility requirements

- Refined CAPEX estimate (±15%)

Detailed Engineering

Phase 3Full construction-ready engineering packages

Key Deliverables

- Fabrication drawings for all equipment

- Structural, civil, and electrical designs

- Instrumentation and control system design

- Safety studies (HAZOP, SIL)

- Final CAPEX estimate (±10%)

Procurement Support

Phase 4Vendor selection, PO placement, manufacturing oversight

Key Deliverables

- Vendor bid evaluation

- Purchase orders for long-lead items

- Manufacturing QA/QC protocols

- Factory acceptance test (FAT) plans

- Shipping and logistics coordination

Construction & Commissioning

Phase 5Site installation, testing, and handover

Key Deliverables

- Site supervision and inspection

- Pre-commissioning checks

- Hot commissioning with feedstock

- Performance test runs

- Operator training and handover

Total typical timeline: 3-6 months for design phases + 8-24 weeks for construction and commissioning = 6-12 months from start of design to first production.

APChemi's engineering team has designed 49+ pyrolysis plants with 12+ patents. Our design process is backed by actual R&D data — not theoretical calculations. Get a free design consultation for your project.

Key Design Parameters & Their Impact

Each of these design decisions significantly affects your plant's performance, costs, and product quality. Understanding the trade-offs is essential:

Reactor Type

Options

Impact on Performance

Determines throughput, heat transfer efficiency, residence time control, and feedstock flexibility

APChemi approach: PYROMAX — multiple patented reactor designs optimized per feedstock type

Heating Method

Options

Impact on Performance

Affects product quality, energy efficiency, and emission profile. Indirect heating prevents contamination of pyrolysis products.

APChemi approach: Indirect heating preferred — cleaner products, easier emission control

Temperature Profile

Options

Impact on Performance

Lower temperatures favor char/wax production; higher temperatures maximize gas and oil. Optimal depends on feedstock and target products.

APChemi approach: Multi-zone control with R&D-optimized profiles per feedstock

Condensation System

Options

Impact on Performance

Multi-stage condensation separates oil into fractions (light, medium, heavy), enabling higher-value product streams and better quality control.

APChemi approach: Multi-stage fractional condensation — maximizes oil quality and value

Gas Handling

Options

Impact on Performance

Syngas recirculation reduces fuel costs by 40-60%. CHP (combined heat and power) generates electricity. Simply flaring wastes energy.

APChemi approach: Syngas recirculation as reactor fuel — energy self-sufficiency

Emission Control

Options

Impact on Performance

Emission control design must match local regulations. Under-designing here means retrofit costs or plant shutdown.

APChemi approach: Multi-stage with CEMS — designed to meet strictest global standards

Plant Layout — Major Sections

A commercial pyrolysis plant consists of eight major sections, each with specific design considerations that affect overall plant performance:

Feedstock Receiving & Storage

Weighbridge, tipping floor, covered storage area, inventory management system

Design Considerations

Size for 7-14 days of feedstock buffer. Separate storage for different feedstock types. Fire protection systems for tire/plastic storage.

Pre-Processing

Shredding, washing, drying, metal separation, size reduction

Design Considerations

Feedstock-specific: plastics need washing + drying; tires need shredding + steel separation; biomass needs drying. Design throughput 120% of reactor capacity for buffer.

Feeding System

Conveyors, hoppers, rotary valves, air-lock feed system

Design Considerations

Must prevent air ingress (oxygen in reactor = explosion risk). Continuous feeding requires precise metering. Design for feedstock variability (density, moisture).

Reactor System

Pyrolysis reactor, heating system, temperature control, residence time control

Design Considerations

The heart of the plant. Material selection (stainless steel / Inconel for high-temp zones), heat distribution uniformity, thermal expansion management. APChemi holds 12+ reactor patents.

Product Recovery

Condensation system, char collection, gas cleaning, oil storage

Design Considerations

Multi-stage condensation for fractional oil recovery. Char cooling and handling (char is hot and can auto-ignite). Gas cleaning before recirculation or use.

Emission Control

Scrubbers, thermal oxidizer, CEMS, stack

Design Considerations

Design for worst-case emissions (feedstock variability). Include continuous monitoring (CEMS) for regulatory compliance. Redundancy for critical systems.

Utilities & Balance of Plant

Electrical systems, cooling water, compressed air, nitrogen supply, fire protection

Design Considerations

Nitrogen blanketing for reactor safety. Cooling water capacity for condensation. Emergency systems (fire, gas detection, emergency shutdown).

Control Room & Automation

PLC/SCADA system, operator interface, data logging, remote monitoring

Design Considerations

Full automation for continuous plants. Recipe management for multi-feedstock. Alarm management and emergency shutdown sequences. Remote monitoring capability.

Designing for ISCC Plus Certification

If your target market includes the EU circular economy or premium certified products, your plant must be designed for ISCC Plus from day one. Retrofitting is expensive and disruptive.

ISCC Plus Design Requirements — Built Into APChemi Plants

Mass Balance System

Automated tracking of feedstock in → products out with mass balance accounting at every conversion step.

Sampling Points

Dedicated sampling ports at feedstock input, reactor output, condensation stages, and final product storage for quality verification.

Segregated Storage

Separate storage tanks/silos for certified and non-certified products. Cross-contamination prevention built into piping design.

Data Logging & Traceability

SCADA system with complete process data logging — temperatures, flows, batch records — required for ISCC audit trail.

QMS Integration

Quality Management System (ISO 9001) and Environmental Management System (ISO 14001) integrated into plant operations from design stage.

GHG Calculation Ready

Energy metering and emission monitoring infrastructure to calculate actual GHG savings — required for ISCC sustainability claims.

Common Design Mistakes That Kill ROI

❌ Under-sizing pre-processing

Pre-processing (shredding, washing, drying) should be designed at 120-150% of reactor capacity. Under-sizing creates a bottleneck that starves the reactor and reduces throughput by 20-30%.

❌ Single-stage condensation

Single-stage condensation produces mixed-quality oil that sells at bottom-tier prices. Multi-stage fractional condensation separates light, medium, and heavy fractions — each commanding different prices and markets.

❌ Inadequate emission control

Designing emission controls to just meet current regulations leaves no margin. Regulations only get stricter. Design for the next standard up, or face expensive retrofit within 3-5 years.

❌ No multi-feedstock flexibility

Designing for a single feedstock is risky — supply chains change. Build in adjustable temperature profiles, modular pre-processing, and switchable operating recipes for feedstock flexibility.

❌ Manual operation when automation is needed

Manual batch plants need 10-20 workers per shift vs 4-8 for automated continuous plants. At commercial scale (20+ TPD), the labor cost difference destroys ROI within the first year.

❌ Skipping R&D testing before design

Designing based on literature data or vendor claims instead of actual feedstock test results leads to 15-40% yield gaps. A $5,000-$15,000 R&D test saves $100K+ in design mistakes.

Modular vs Custom Design

| Factor | Modular (Pre-Engineered) | Custom (Bespoke) |

|---|---|---|

| Design Time | 2-6 weeks (adaptation) | 12-24 weeks (from scratch) |

| Total Project Time | 6-12 months | 12-24 months |

| Cost | Lower (proven design reuse) | 20-40% premium |

| Performance Risk | Low (validated design) | Medium (first-of-kind elements) |

| Flexibility | Standard configurations | Fully optimized for requirements |

| Scalability | Easy (add modules) | Requires new engineering |

| Best For | Standard feedstocks, proven applications, fast deployment | Unique feedstocks, special requirements, large scale |

APChemi recommendation: Start with a modular design based on proven platforms. APChemi's modular designs have been validated across 49+ plants and can be adapted to your specific requirements with minimal risk and shorter timelines.

Powered by APChemi — 49+ Plants Designed and Delivered

Frequently Asked Questions

Conceptual design takes 2-4 weeks, basic engineering (FEED) takes 4-8 weeks, and detailed engineering takes 6-16 weeks depending on plant complexity. Total design phase: 3-6 months. For plants based on proven designs (like APChemi's modular platforms), the timeline is shorter since the core engineering is already validated across 49+ projects.

At minimum: (1) Feedstock type and composition, (2) Available quantity per day, (3) Desired products and quality specs, (4) Site location and constraints, (5) Budget range, (6) Regulatory requirements. Ideally, feedstock should be tested in an R&D facility first — APChemi's lab can analyze any feedstock and provide precise yield data that feeds directly into the design.

Batch is simpler and cheaper (suitable for 1-15 TPD, $50K-$400K), but has lower efficiency, inconsistent product quality, and can't achieve ISCC certification. Continuous is recommended for 15+ TPD commercial operations — higher uptime (80-92%), consistent quality, lower per-unit costs, and ISCC eligibility. APChemi recommends continuous for any serious commercial project.

Yes — multi-feedstock flexibility is one of APChemi's design specialties. However, each feedstock has different optimal processing conditions (temperature, residence time, pre-processing). A well-designed plant includes adjustable parameters, modular pre-processing, and switchable operating profiles. This is significantly more complex than single-feedstock design and requires R&D testing of each feedstock.

Modular plants use pre-engineered, factory-built modules that are assembled on-site — faster deployment (6-12 months), lower risk, proven performance. Custom-built plants are engineered from scratch for unique requirements — longer timeline (12-24 months), higher cost, but optimized for specific conditions. APChemi offers both: standardized modular platforms for common applications and custom designs for complex projects.

Significantly. ISCC Plus requires: mass balance accounting systems, product traceability from feedstock to output, quality management (ISO 9001), environmental management (ISO 14001), and specific documentation capabilities. Plants must be designed with dedicated sampling points, segregated storage, and automated tracking. Retrofitting ISCC requirements onto an existing plant is much more expensive than designing them in from the start.

Get a Free Consultation

Tell us about your pyrolysis project and our engineers will get back to you within 24 hours.

Explore More

Pyrolysis Plant Cost

How design choices affect your total investment.

Pyrolysis Plant Manufacturer

Choose a manufacturer with proven design capability.

R&D / Lab Testing

The feedstock data that drives plant design.

Continuous Pyrolysis

Design considerations for continuous operation.

Oil Purification

Downstream design for maximum oil value.

Contact APChemi

Discuss your plant design requirements.