ISO 9001:2015 Certified

ISO 9001:2015 Certified  CE Marking Aware

CE Marking Aware  ATEX Compliant Engineering

ATEX Compliant Engineering  Lloyd's Register Trained

Lloyd's Register Trained Engineering Credentials at a Glance

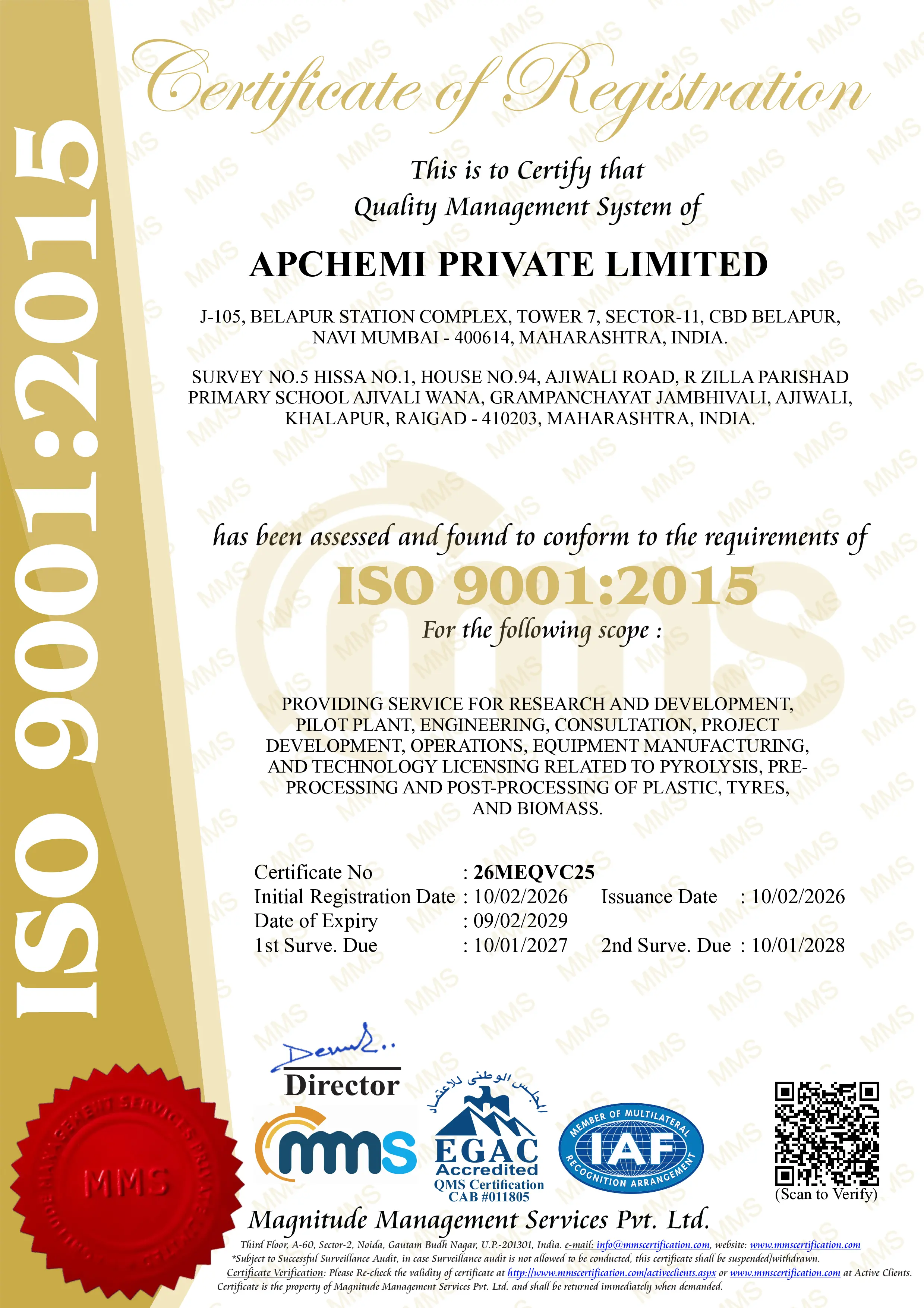

ISO 9001:2015 — Certified Engineering Excellence

APChemi's Quality Management System is ISO 9001:2015 certified (Certificate No. 26MEQVC25), verified by Lloyd's Register (LRQA) for European and global markets. The certification scope covers:

- Research and Development

- Pilot Plant Engineering

- Engineering, Consultation, and Project Development

- Operations, Equipment Manufacturing, and Technology Licensing

- Pre-processing and Post-processing of Plastic, Tyres, and Biomass

Certificate Details

- Certificate No.

- 26MEQVC25

- Standard

- ISO 9001:2015

- Issued

- 10 Feb 2026

- Expires

- 09 Feb 2029

- Certifying Body

- MMS Certification (IAF)

Global Engineering Track Record

APChemi's engineering discipline is validated by a proven track record of delivering high-capacity infrastructure to the world's most demanding energy markets.

Clean Planet Energy — United Kingdom

Complete engineering of a 42 metric tonne per day continuous plastic pyrolysis plant, approved by British owners' engineers STOPFORD in full compliance with CE and ATEX safety directives.

Equate Petrochemicals — Kuwait

Deliverables met over 1,700 pages of rigorous global standards for process safety, mechanical integrity, electrical & automation, and information management — for Dow Chemical's JV with the Government of Kuwait.

The "Gold Standard" in Pyrolysis Design

Across 49+ industry-scale assignments, APChemi has developed proprietary engineering standards that set the benchmark for pyrolysis, pre-processing, and post-processing technologies.

Chemical Engineering

Process design, mass & energy balance, reaction engineering

Mechanical Engineering

Reactor design, pressure vessels, structural integrity

Electrical & Automation

Control philosophy, SCADA, PLC programming, safety interlocks

Technical Recovery

APChemi leverages superior design standards to diagnose and solve performance issues in underperforming third-party pyrolysis projects, turning failing assets into operational successes.

Request our Technical Safety Dossier — including original certifications and project documentation

The APChemi Standard

In the chemical recycling industry — where failure rates often exceed 80% — technical reliability is the only path to scalability. APChemi eliminates operational risk by integrating rigorous European and American Design and Safety Standards into every project phase.

Our core engineering team has undergone specialised training and evaluation by Lloyd's Register, the world's leading authority in technical audit and safety certification.

Standards We Engineer To

HAZOP, SIL assessment, LOPA, explosion protection, hazardous area classification

ASME, PED (2014/68/EU), pressure vessel design, piping stress analysis

IEC 60079 (Ex equipment), IEC 61511 (SIS), NEC/NFPA standards

ISA-88/95, PLC/SCADA design, safety PLC (SIL-rated), DCS integration

EU Industrial Emissions Directive, emission monitoring, waste heat recovery

Document control, engineering change management, handover documentation

European Directive Alignment

APChemi ensures that all engineering and technology solutions meet the stringent requirements of the European Union:

ATEX Compliance

ATmosphères EXplosibles

Compliance with EU Directive 2014/34/EU for equipment and protective systems in potentially explosive atmospheres.

- ● Hazardous area classification (zones 0, 1, 2)

- ● Ex-rated equipment selection and specification

- ● Gas detection and explosion protection systems

- ● Electrical installation in hazardous areas

CE Marking

Conformité Européenne

Strict adherence to EU health, safety, and environmental protection standards across multiple directives:

- ● Machinery Directive (2006/42/EC)

- ● Pressure Equipment Directive (2014/68/EU)

- ● Low Voltage Directive (2014/35/EU)

- ● EMC Directive (2014/30/EU)

Professional Training Verification

APChemi's core engineering team has completed specialised training through Lloyd's Register (LRQA), covering ATEX compliance, CE marking requirements, and European safety directive implementation for industrial process plants.

Lloyd's Register — Verified Training

Our engineers hold verified certifications in ATEX compliance and CE marking from Lloyd's Register, the world's leading authority in technical audit and safety certification, with over 260 years of heritage in engineering safety.

Note on Data Privacy: Engineer names have been redacted for privacy. APChemi maintains a full register of unredacted certificates for authorized auditors during formal due diligence.

Refinery Due Diligence & Vendor Audits

For investors, project developers, and petrochemical companies conducting formal due diligence, APChemi provides a comprehensive Technical Safety Dossier including:

Frequently Asked Questions

APChemi is ISO 9001:2015 certified (Certificate No. 26MEQVC25, verified by MMS Certification under IAF accreditation). Our engineering team has completed specialised ATEX and CE Marking compliance training through Lloyd's Register (LRQA), the world's leading authority in technical audit and safety certification. These credentials cover our full scope: R&D, pilot plant engineering, consultation, project development, operations, equipment manufacturing, and technology licensing for pyrolysis of plastic, tyres, and biomass.

Pyrolysis involves processing flammable materials at 400-700°C, producing combustible gases and oils. Without rigorous safety engineering, plants face explosion risks, toxic emissions, and equipment failure. In an industry where failure rates exceed 80%, certified engineering standards are the difference between a profitable operation and a costly shutdown. ATEX compliance ensures equipment is safe in explosive atmospheres, CE marking confirms EU safety standards, and ISO 9001 ensures consistent quality management across all project phases.

ATEX (ATmosphères EXplosibles) refers to EU Directive 2014/34/EU governing equipment and protective systems for use in potentially explosive atmospheres. Pyrolysis plants generate flammable gases (syngas, pyrolysis vapours) and handle combustible materials, making ATEX compliance critical. APChemi's ATEX-compliant engineering ensures proper hazardous area classification, appropriate equipment selection (Ex-rated motors, instrumentation), gas detection systems, and explosion protection measures throughout the plant.

CE (Conformité Européenne) marking indicates that pyrolysis equipment meets EU health, safety, and environmental protection requirements. For pyrolysis plants destined for European markets, CE marking covers the Machinery Directive (2006/42/EC), Pressure Equipment Directive (2014/68/EU), Low Voltage Directive (2014/35/EU), and EMC Directive (2014/30/EU). APChemi's 42 TPD plant for Clean Planet Energy (UK) was fully CE and ATEX compliant, approved by British owners' engineers STOPFORD.

Yes. APChemi maintains a comprehensive Technical Safety Dossier for authorized auditors and investors conducting formal due diligence. This includes original ISO 9001:2015 certificates, Lloyd's Register training verification, ATEX and CE compliance documentation, and UK/Kuwait project documentation demonstrating standards adherence. Engineer names are redacted for privacy, but full unredacted registers are available under NDA for qualified auditors. Contact us to request the dossier.

Get a Free Consultation

Tell us about your pyrolysis project and our engineers will get back to you within 24 hours.

Explore More

ISCC Plus Certification

Sustainability certification for pyrolysis oil, biochar, and recycled carbon black.

Choosing a Manufacturer

How to evaluate pyrolysis plant suppliers — certifications, track record, and red flags.

Plant Design Guide

Engineering design phases, parameters, and safety standards for pyrolysis plants.

Project Management (PMC)

End-to-end project management from engineering to commissioning.

R&D / Lab Testing

Pilot-scale testing at APChemi's dedicated R&D facility.

Contact APChemi

Request our Technical Safety Dossier or discuss your project requirements.