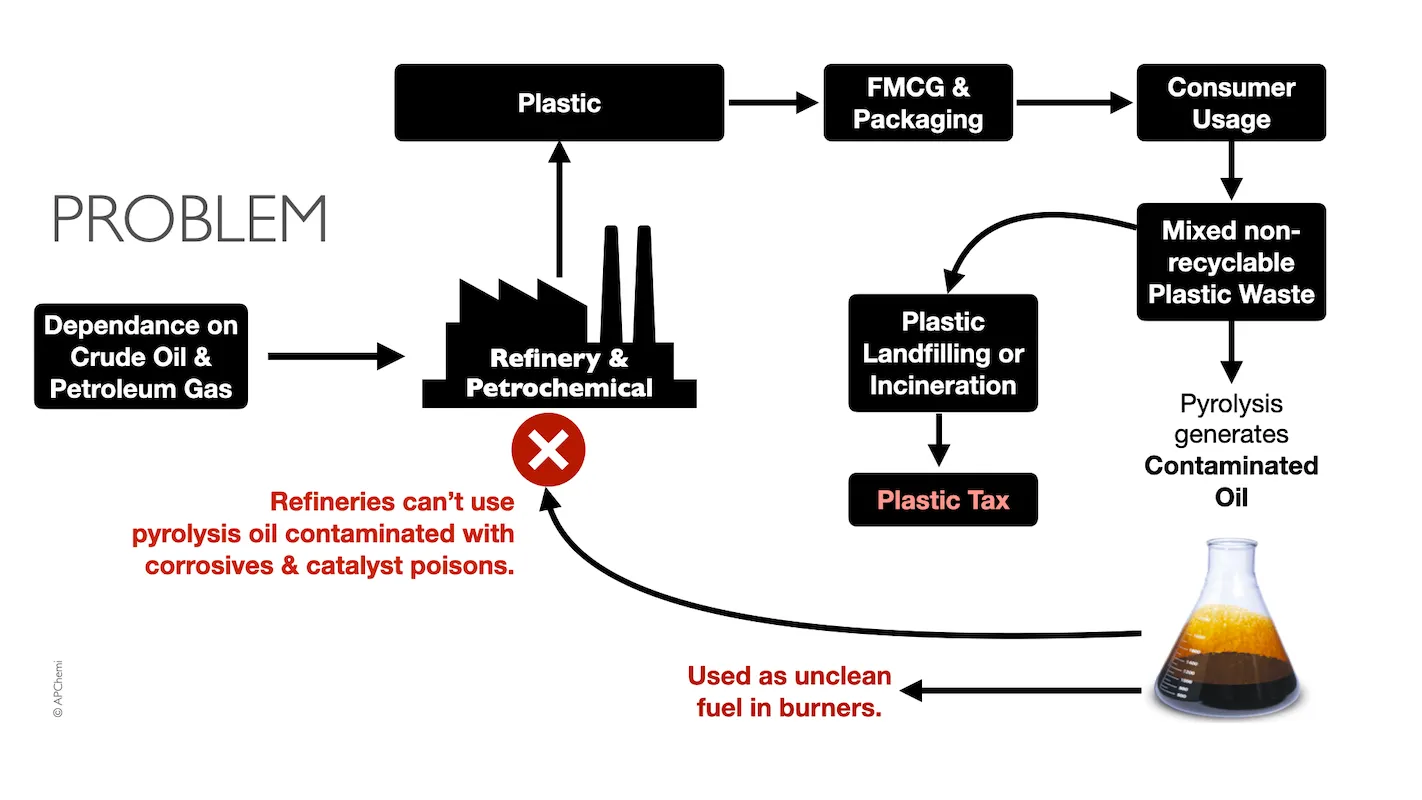

* Industry estimate: majority of low-cost plants from unvetted manufacturers underperform or shut down within 3 years

Why Your Manufacturer Choice Matters More Than You Think

The pyrolysis industry has a dirty secret: the majority of plants built with cheap, unproven equipment fail to meet their projected performance. The consequences are severe:

❌ What Goes Wrong with Poor Manufacturers

- ✗ Oil yields 15-40% below claims — vendor said 80%, plant delivers 50-60%

- ✗ Reactor failures in Year 1 — poor metallurgy, inadequate heat distribution

- ✗ No after-sales support — manufacturer disappears after final payment

- ✗ Emission non-compliance — plant can't meet local regulations, faces shutdown

- ✗ Can't get ISCC certified — plant design doesn't support mass balance requirements

✅ What Proven Manufacturers Deliver

- ✓ Yields match or exceed projections — backed by R&D test data, not guesses

- ✓ Equipment runs 80-92% uptime — designed for continuous commercial operation

- ✓ Full commissioning + training — your team is fully operational before handover

- ✓ Regulatory compliance built-in — emission controls designed for your jurisdiction

- ✓ ISCC-ready from design stage — mass balance, traceability, and QA systems included

How to Evaluate a Pyrolysis Plant Manufacturer

Use this systematic evaluation framework when comparing manufacturers. Weight each category according to your project priorities:

Track Record

- Number of commercial plants delivered (not just sold)

- Years of continuous operation in reference plants

- Diversity of feedstock experience (plastic, tire, biomass)

- Client references you can actually contact

- Published case studies with verifiable data

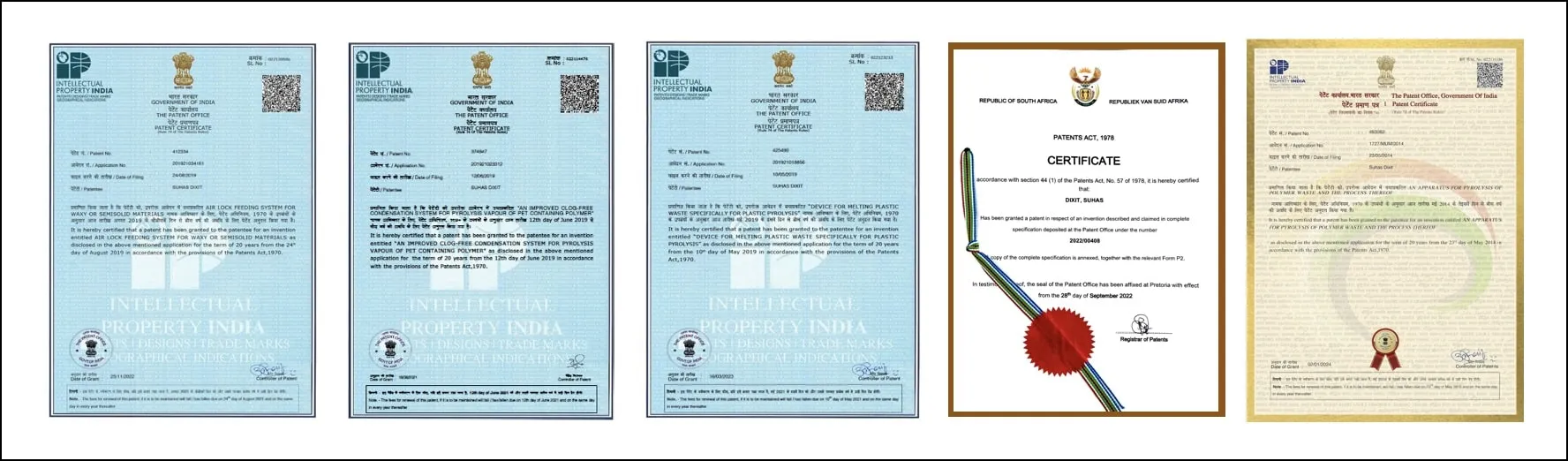

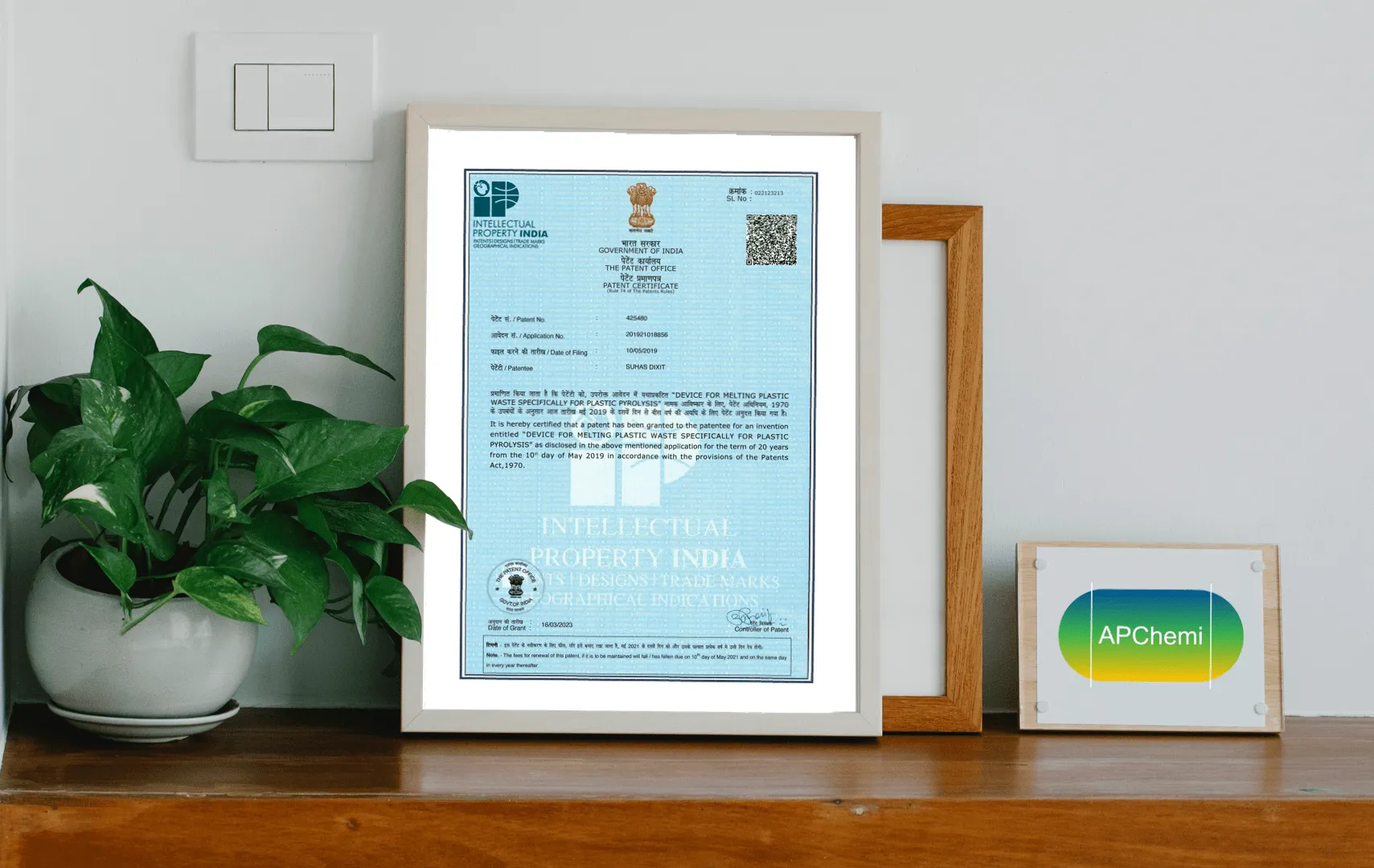

Technology & IP

- Proprietary patents vs assembled third-party components

- R&D facility and ongoing technology development

- Process yield data from actual operations (not simulations)

- Reactor design maturity and generation count

- Oil purification/distillation capability

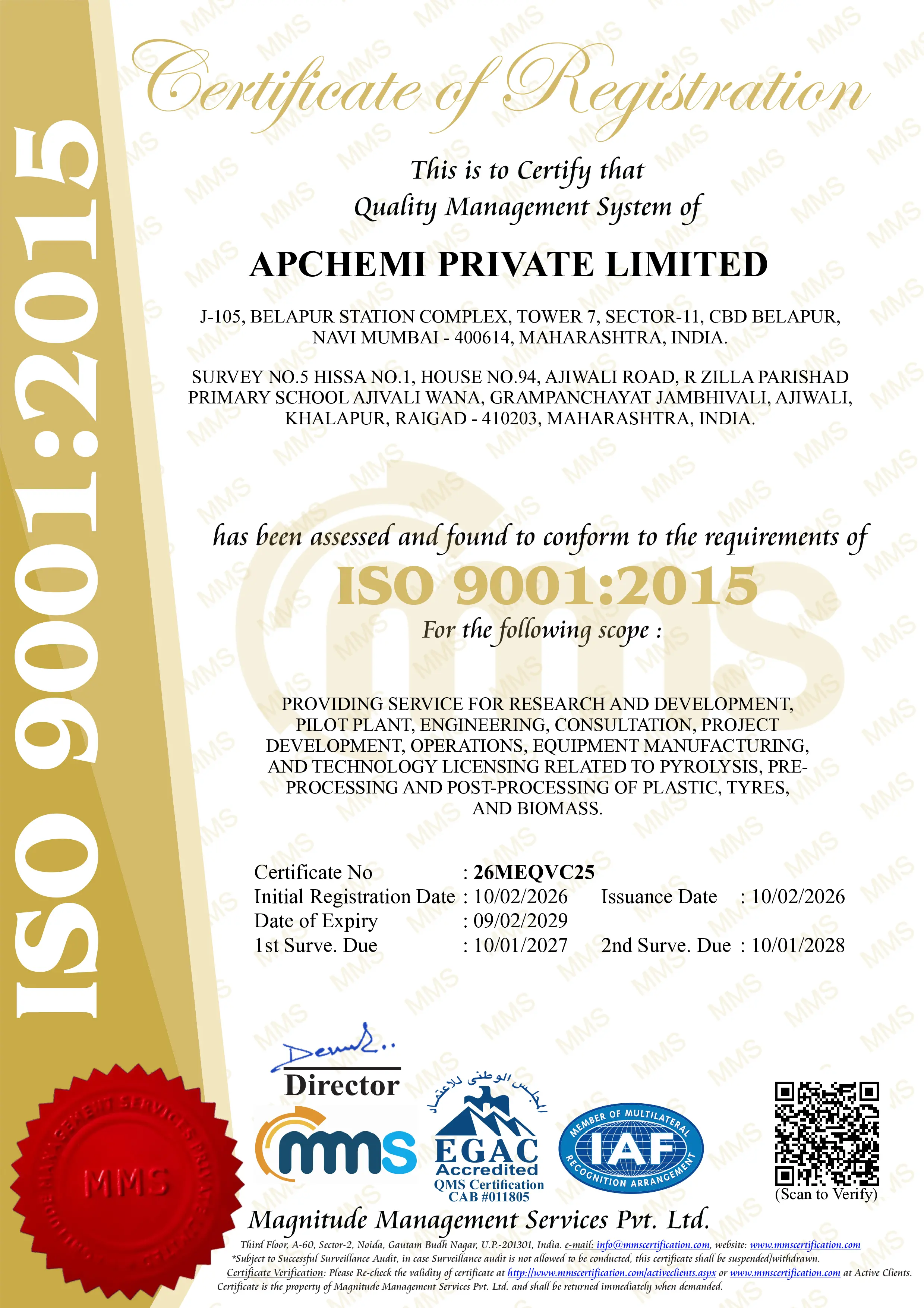

Quality & Certifications

- ISO 9001, ISO 14001, CE marking

- ASME/PED compliance for pressure equipment

- ISCC Plus certification capability for output products

- Third-party quality audits and inspection protocols

- Material certificates and component traceability

After-Sales & Support

- Commissioning support and operator training included

- Spare parts availability and lead times

- Remote monitoring and troubleshooting capability

- Warranty terms (equipment, performance, yield guarantees)

- Long-term service and maintenance agreements

Financial Stability

- Company age, revenue, and financial health

- Insurance coverage for project delivery

- Escrow or milestone-based payment terms

- Bank guarantees or performance bonds

- Reference banking and credit checks

Project Execution

- In-house engineering team size and capability

- EPC / turnkey delivery capability

- Project management methodology and tools

- Site supervision and commissioning team

- Timeline adherence track record

Not sure which manufacturer to choose? APChemi has delivered 49+ pyrolysis plants with 12+ patents and 17+ years of experience. Get a free consultation to discuss your project requirements and find the right solution.

Red Flags — When to Walk Away

The pyrolysis industry attracts companies of widely varying quality. These warning signs should trigger serious caution — or disqualification:

🚩 No verifiable reference plants

If a manufacturer can't connect you with existing clients running their equipment, that's a major risk. Ask for site visits.

🚩 Oil yield claims above 90%

No real pyrolysis plant consistently achieves 90%+ oil yield from mixed plastic. Claims above 85% for any feedstock should be verified with independent test data.

🚩 No patents or proprietary technology

Manufacturers who assemble commodity components add no IP value. When problems arise, they have no deep expertise to solve them.

🚩 Payment 100% upfront

Legitimate manufacturers work with milestone-based payments (30-40-20-10 or similar). Full upfront payment offers zero leverage.

🚩 No performance guarantee

A confident manufacturer guarantees throughput capacity, minimum yield, and emission compliance. No guarantee = no accountability.

🚩 "Cheapest price" as main selling point

If the pitch is purely about lowest cost, the manufacturer is competing on price because they can't compete on quality or capability.

🚩 No after-sales team or spare parts plan

Equipment will need maintenance and parts. A manufacturer without a spare parts supply chain will leave you stranded.

🚩 Resistance to third-party inspection

Professional manufacturers welcome quality inspections during manufacturing. Resistance suggests quality issues.

Manufacturers by Region

The pyrolysis plant manufacturing landscape varies dramatically by region. Here's an honest comparison of what each region offers:

China

Equipment: $20K - $500KStrengths

- ✓ Lowest equipment prices (30-50% cheaper)

- ✓ Huge manufacturing capacity

- ✓ Wide range of plant sizes available

- ✓ Short manufacturing lead times

Weaknesses

- ✗ Variable quality — wide range from poor to decent

- ✗ Limited after-sales support outside China

- ✗ IP concerns and technology copying

- ✗ Communication and language barriers

- ✗ Spare parts logistics can be slow

Best for: Budget-constrained pilot projects where the operator has in-house engineering capability

India

Equipment: $30K - $3M+Strengths

- ✓ Competitive pricing with strong engineering

- ✓ Growing R&D and patent portfolio

- ✓ English-speaking technical teams

- ✓ Strong in process engineering and design

- ✓ APChemi: 49+ projects, 12+ patents, ISCC expertise

Weaknesses

- ✗ Fewer manufacturers than China

- ✗ Some lack international project experience

- ✗ Verify certifications carefully

Best for: Mid-to-large scale projects needing proven technology, R&D-backed design, and ISCC certification at competitive cost

Europe

Equipment: $200K - $10M+Strengths

- ✓ Highest quality and regulatory compliance

- ✓ CE marking and ISCC infrastructure built-in

- ✓ Strongest IP protection and patents

- ✓ Premium after-sales and remote monitoring

- ✓ Best for ISCC/circular economy markets

Weaknesses

- ✗ 20-40% cost premium over Asian manufacturers

- ✗ Longer lead times (6-12 months)

- ✗ Limited capacity for large order volumes

Best for: ISCC-certified commercial plants in regulated markets (EU, UK, North America) where quality and compliance are paramount

North America

Equipment: $250K - $5M+Strengths

- ✓ Local presence and support

- ✓ IRA tax credit eligibility

- ✓ US regulatory compliance built-in

- ✓ Growing number of technology providers

Weaknesses

- ✗ Limited number of specialized manufacturers

- ✗ Highest cost per unit of capacity

- ✗ Most are technology licensors, not manufacturers

Best for: US-based projects seeking IRA incentives and requiring domestic content requirements

Questions to Ask Every Manufacturer

Before signing a contract, get clear answers to these questions. A manufacturer that can't answer them confidently is a manufacturer you should avoid:

Due Diligence Questions Checklist

"How many commercial plants are currently operating with your equipment?"

Accept only plants you can verify. "Installed" ≠ "operating successfully."

"Can I visit a reference plant and speak with the operator?"

If they can't arrange this, question why.

"What are the guaranteed yield specifications for my feedstock?"

Get it in writing. No guarantee = no accountability.

"Have you tested my specific feedstock in your R&D facility?"

Lab-tested yields are far more reliable than theoretical claims.

"What patents do you hold related to pyrolysis technology?"

Patents indicate genuine R&D investment and unique capability.

"What emission levels will the plant achieve? Can you guarantee compliance?"

Get specific numbers and standards, not vague promises.

"What's the spare parts availability and lead time?"

A broken reactor with 6-month spare parts lead time = disaster.

"Can your plants achieve ISCC Plus certification?"

Critical for accessing premium markets and green financing.

Why APChemi — 49+ Plants, 12+ Patents, 17+ Years

APChemi's plants are engineered to be 7x better — delivering measurable advantages across energy efficiency, safety, raw material flexibility, cost efficiency, anti-coking technology, scalability, and oil purity. Few manufacturers can match this combination:

49+ Commercial Plants

Not prototypes or pilot units — real commercial plants processing waste daily across multiple countries. APChemi has processed 227M+ kg of feedstock through its designs.

Own R&D Facility

In-house laboratory and pilot plant for testing any feedstock. Yield claims are backed by actual test data — not literature values or theoretical models.

12+ Patents

Proprietary patent-protected technology including the PYROMAX reactor and PUREMAX oil purification system. APChemi innovates — not copies.

Oil Distillation Plant

APChemi owns and operates a fractional distillation plant for pyrolysis oil — unique expertise in oil purification and product upgrading that no other manufacturer offers.

ISCC Plus Experts

3+ plants guided through ISCC Plus certification — opening premium markets for recycled content. APChemi designs plants with certification requirements built in from day one.

End-to-End Service

Feasibility → R&D testing → design → procurement → construction management → commissioning → operations support. Single point of responsibility for your project.

Powered by APChemi — The Manufacturer with Proof

Frequently Asked Questions

Chinese manufacturers offer the lowest upfront cost (30-50% cheaper) but with variable quality, limited after-sales support, and potential IP concerns. European manufacturers cost more (20-40% premium) but deliver higher quality, ISCC/CE compliance, stronger patents, and better long-term support. Indian manufacturers like APChemi offer a middle ground — competitive pricing with strong engineering capability. The right choice depends on your scale, certification needs, and risk tolerance.

Look for ISO 9001 (quality management), ISO 14001 (environmental management), CE marking (for EU sales), ASME/PED compliance (pressure equipment), and critically — whether their plants can achieve ISCC Plus certification (required for circular economy markets). Also check for patents: manufacturers with proprietary technology have more skin in the game. APChemi holds 12+ patents and has guided 3+ plants through ISCC Plus certification.

Turnkey (single EPC provider) is recommended for most projects. It provides a single point of accountability, integrated design, tested systems, and clear warranty terms. Multi-sourcing is cheaper on paper but creates interface risks, finger-pointing during commissioning, and no single party responsible for plant performance. APChemi provides full turnkey solutions including design, procurement, construction supervision, and commissioning.

APChemi has designed and delivered 49+ pyrolysis and thermochemical plants worldwide across 17+ years. This includes biomass pyrolysis (biochar/CDR), tire pyrolysis, plastic pyrolysis, and gasification plants. APChemi also owns and operates a pyrolysis oil fractional distillation plant and an R&D facility for feedstock testing. The company holds 12+ patents and has guided 3+ plants through ISCC Plus certification.

Equipment manufacturing typically takes 4-8 months depending on capacity and complexity. Full turnkey project timelines (design → manufacturing → civil works → installation → commissioning) range from 8-18 months. Smaller batch plants can be delivered in 4-6 months. Budget an additional 2-6 months for permitting and site preparation. APChemi provides detailed project schedules during the proposal phase.

Importing is common and often necessary — there are few pyrolysis plant manufacturers in most countries. Key considerations: import duties (0-15% depending on country), shipping costs ($15K-$80K for containerized equipment), local installation requirements, and after-sales support logistics. Many clients import equipment from India/Europe and use local contractors for civil and electrical works under the manufacturer's supervision.

Get a Free Consultation

Tell us about your pyrolysis project and our engineers will get back to you within 24 hours.

Explore More

Pyrolysis Plant Cost

Detailed pricing by capacity, type, and region.

Pyrolysis Plant Design

How plant design affects performance and ROI.

R&D / Lab Testing

Test your feedstock before committing to a manufacturer.

ISCC Certification

Ensure your manufacturer can deliver ISCC-ready plants.

Case Studies

See APChemi's 49+ delivered plant projects.

Contact APChemi

Discuss your project requirements with our engineering team.